What you will learn in our blacksmithing classes

Do you watch every new episode of "Forged in Fire" and want to start a new hobby with endless creativity? Maybe blacksmithing is for you. Before you run out and buy an anvil and hammers, you might want to consider starting with a hands-on workshop.

What you'll learn in the basic class

In the Sentinel Forge basic class, we have six stations with a basic anvil set up. Each spot includes an anvil stand and all the tooling you need for your class. We will use hands-on projects to learn blacksmithing skills and how to handle all the proper tools.

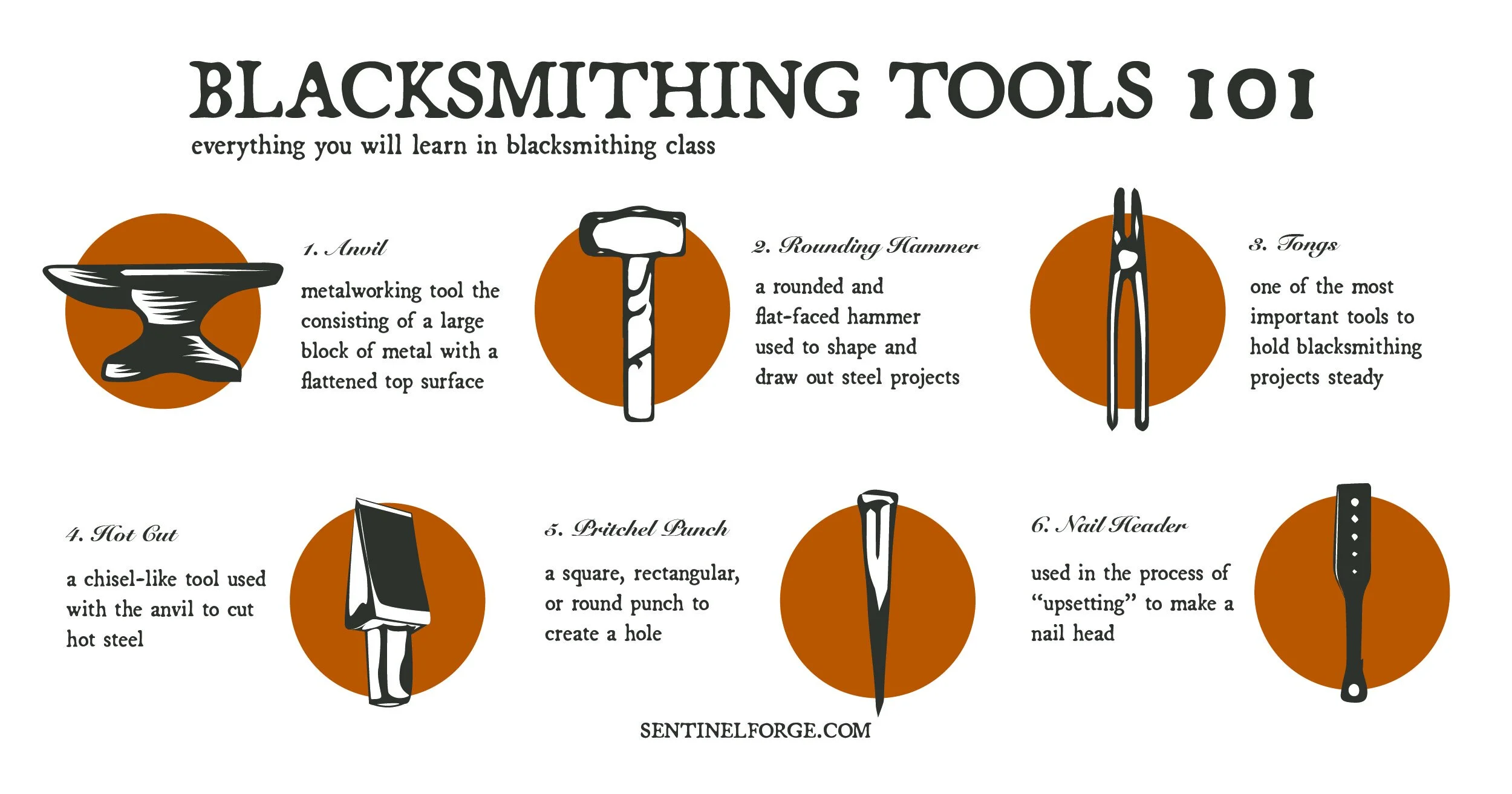

Tools used in blacksmithing

Anvil

The most important tool you will be learning to use is the anvil. We will go over the different parts of the anvil; like the top or working face, the horn, the cutting table, the step, and heel, and the hardy hole. Even the outside and inside edges of the anvil become tools in our basic forging class.Rounding Hammer

A rounding hammer is used for almost all blacksmithing projects to shape and draw out steel faster than a flat-faced hammer. As the name suggests one end of the hammer has a rounded surface while the other end is flat for smoothing. This is a perfect tool for a beginner in our class because it saves you time and energy.Tongs

Arguably one of the most important tools for blacksmithing is tongs. In our classes, we use standard straight-bit tongs set up for 1/4" stock. While one of the most important tools in the shed, it's also one of the weakest points in the blacksmithing system because you need to be able to use it confidently with your non-dominate hand. This tool takes the longest to learn.Hot Cut

As the name implies, a hot cut is like a chisel used to cut hot steel. You place the chisel in the "hardy hole" of the anvil, place the hot steel on top, and hammer. It will create a cut in the steel that will allow you to bend the material with a pair of tongs to separate the parts.Pritchel Punch

The Pritchel Punch is used in conjunction with the Pritchel hole on the anvil. The pritchel punch is traditionally used in forging the nail holes in a horseshoe but can be used to punch a hole in any piece of hot steel. In the basics class, we use the punch to make a nail hole in a wall hook. These punches can be square, rectangular, or round.Nail Header

The nail header is used in the process of "upsetting" to make the head of the nail. While creating a nail, the blacksmith will place the hot section of the steel into the hole of the tool, and use the hammer to flatten the head.

Blacksmithing skills

Throughout the full-day basic class, you will create projects like a nail and a hook so that you can learn the seven fundamental skills of blacksmithing.

Drawing Out

The process of drawing out is making a bar longer and skinnier. Drawing doesn't have to be uniform. A blacksmith can taper the steel making a wedge or a chisel blade. Drawing can be accomplished through several different methods but one of the most common methods is with a hammer and anvil.Bending

Heating iron to "forging heat" allows a blacksmith to bend, twist, and mold a project in to any shape. The process of bending typically is done with a hammer over the horn or edge of the anvil.Upsetting

Upsetting is the process of making metal thicker at one point, but shortening in another dimension. One example of upsetting students learn in the Sentinel Forge Basic Class is creating the head of a nail. In this example, the blacksmith heats up one end of the rod and hammers it down as if you were hammering a nail. The whole rod gets shorter while the hot end flattens out into the head of the nail.Punching

The process of punching is used to make holes or a decorative pattern. In this process, a blacksmith uses a tool called a punch to break through the material when heated to forging heat. Punching is not limited to depressions and holes, it can include processes like cutting.Spreading

Similar to the drawing and tapering process, this skill is also about moving the material. However, instead of making the material longer and skinnier, the goal is to spread the material along the other axis.Subtractive

Subtractive processes include methods like cutting, filing, and grinding. This process is removing material from the project.Additive

The additive process is any method that adds material to the project. That can be done in forge welding, combining the material with rivets or collar welds.

Learn advanced metal-working skills in a knife-making or hatchet-making class

Once you have the basics of blacksmithing down like tool handling and forging techniques you can move on to a project-based class to build on those new skills. These are particularly fun classes to learn techniques to make cutlery, hatches, or blacksmithing tools.

If you're interested in the historic process of blacksmithing, farrier work, knife making, hatchet making, or just a fun weekend activity blacksmithing might be for you! Almost anyone can take our classes to learn the basics of blacksmithing. You can even dive in a little deeper on your own schedule and start with our free Beginner's Guide to Becoming a Blacksmith.

We hope to see you at the forge!